At our Lannach location, we have specialised in thermal coating, among others. We offer technical coatings that render the surfaces of metallic workpieces especially wear and corrosion-resistant or give them a specific function (thermal/electrical insulation or conductivity). These properties are of great importance for many technical applications.

Our functional coatings increase the life cycle of parts and thus increase the service life of machines and plants. Moreover, our coatings can be used to rehabilitate expensive parts.

Lannach

ø: 3,000 mm

Length: 4,000 mm

Weight: 5,000 kg

We coat workpieces with a max. diameter of 3,000 mm, a max. length of 4,000 mm and a max. weight of 5.000 kg.

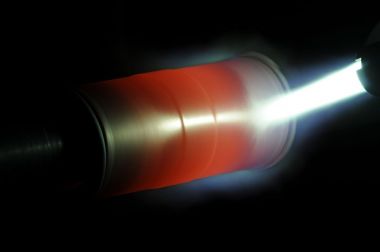

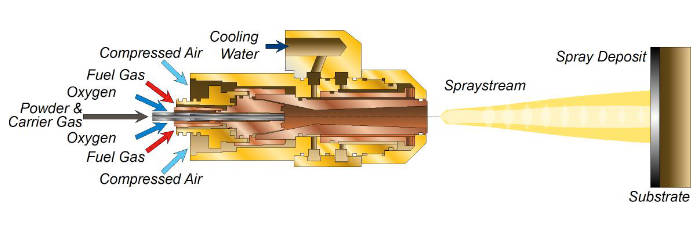

Our technologies such as fuel spraying with wire and powder, high-velocity oxygen fuel spraying (HVOF) and plasma as well as light arc spraying make us specialists in the field of thermal spraying. In the course of these coating methods that can be applied in three booths at the same time, your workpieces are given an extremely effective functional coating. For you, this results in massive cost savings and minimal downtimes.

We work with proven technologies at the latest state of technology and do not stress the material with more than 100° C (except for re-melting method). We can thus coat all metallic base materials. Careful preparation of the coating surface by means of degreasing and sand-blasting is a prerequisite for optimal coat adhesion.

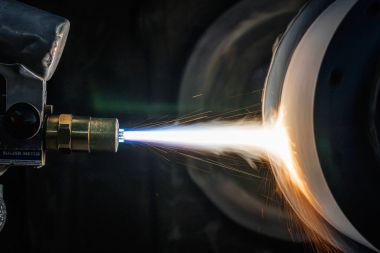

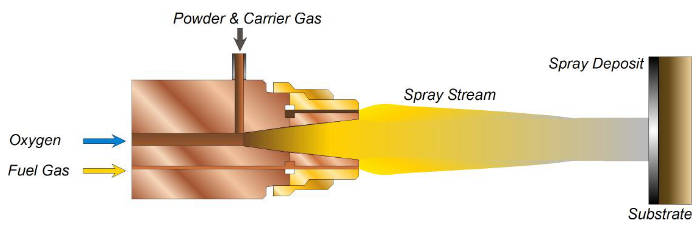

High-velocity oxygen fuel spraying (HVOF)

Main properties:

- Hard and dense coat with fine and homogeneous structure and high chemical purity

- Coat strongly bonds with material

Typical applications:

- Glide surfaces (piston rods)

- Sealing surfaces (shaft sleeves)

- Abrasion, erosion and wear resistance (hydro)

- Valves

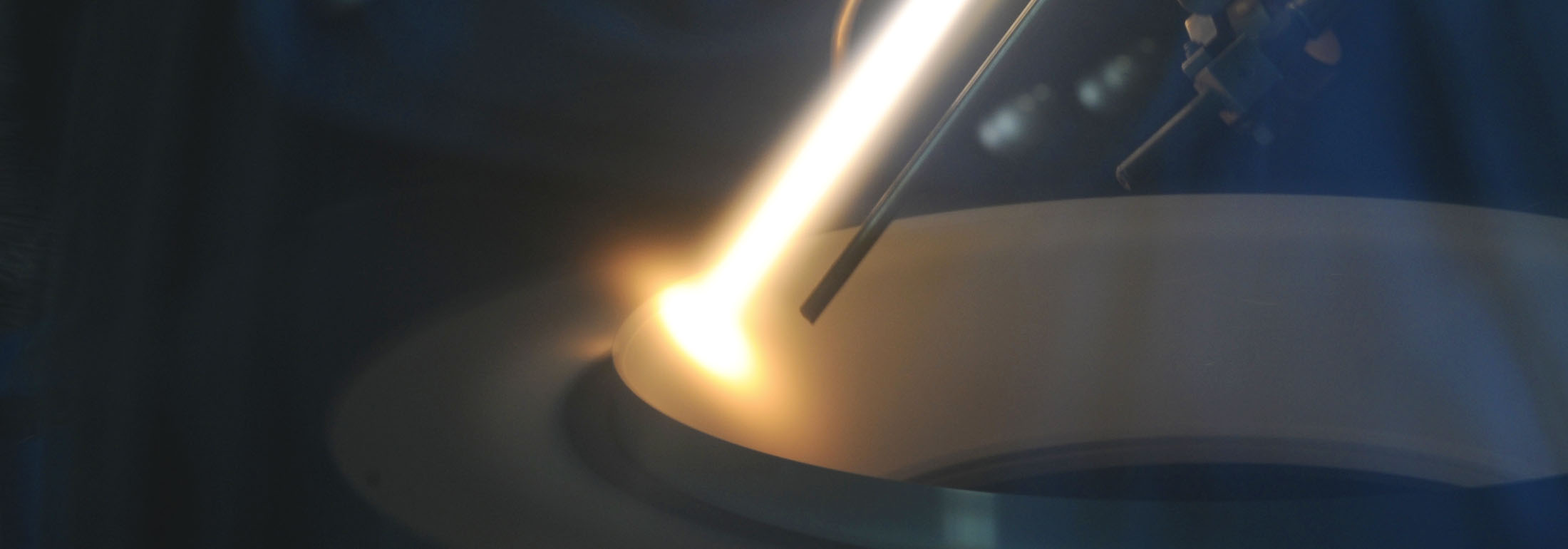

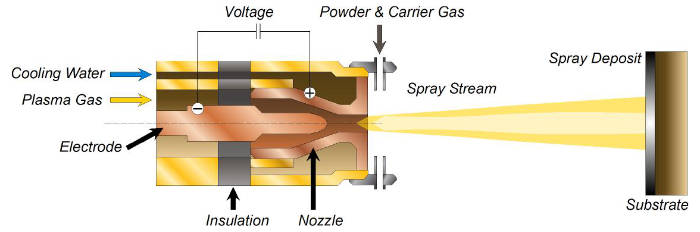

Plasma spraying

Main properties:

- The most flexible of all thermal spraying methods; has enough energy to melt any material

- Coat strongly bonds with material

Typical applications:

- Chemical resistance (Chromium oxide)

- Thermal insulation (Aluminium oxide)

- Functional coats (Aluminium titanium oxide etc.)

- Rough coatings (Drive rollers)

- Anti-adhesion

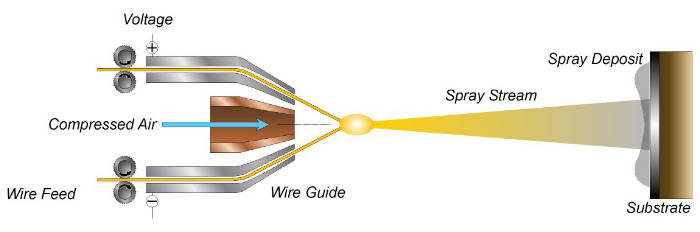

Light arc spraying

Main properties:

- High spray rate

- Only electrically conductive wires can be coated

Typical applications:

- Corrosion protection

- Slide bearings

Fuel spraying with wire and powder

Main properties:

- High spray rate

- Produces very thick coats

Typical applications:

- Repairs

- Metallic coatings

- Building up a base coat to use re-melting technique later on

Applications and special features:

Applications

Rail vehicles, ships, aircraft, power plants, motorsports, industrial plants and more

Advantages

Almost every metallic workpiece can be thermally coated; no thermal changes to the workpiece’s structure; high dimensional precision; flexibility in use

Browse our processing and reference gallery: